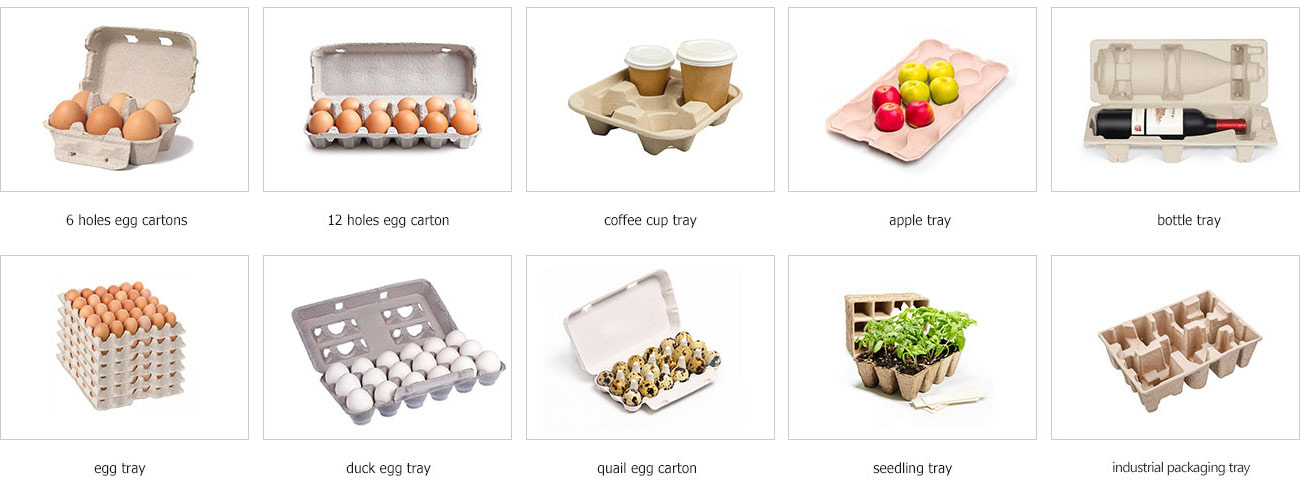

The Paper Pulp Molding Machines are used for making egg cartons, egg trays, fruit trays, apple trays, coffee-cup trays, and bottle trays. These end products are typically produced from recycled paper that is often recycled again.

With these machines, waste paper in large amounts can be handled in an eco-friendly and effective way. For this reason, paper pulp molding equipment has played a vital role in the industry of packaging.

How Is Molded Pulp Made? The Paper Pulp Molding Process

Molded pulp is produced from recycled or waste paper. The manufacturing process involves four important steps. According to one of the reputable pulp molding machine manufacturers, here is how molded pulp is made in one of these machines.

The Pulp Making Process

– Rough Pulp Form

The raw materials which are usually made up of waste cartons, waste newspaper or waste paper are placed into the hydraulic pulper. With the addition of water, the waste paper is broken down into rough pulp.

– Pulp Adjustment

The pulp then flows into a homogenization pool where it is further refined with a pulp beater.

The Molding Process

– Pulp Supply

Appropriate percentages of the pulp flow into a “finished pulp” pool. The pulp pump will then transport the pulp into a fully automatic egg tray making machine.

– Molded Pulp Forming

In this stage of the process, a vacuum pump is used to suck the pulp up onto the molds that are used to form egg cartons, trays, or any other end product. From here an air compressor is used to produce a blowing force, which causes the final product to drop away from the molds.

The Drying Process

The molding products are still wet at this stage. From here they are conveyed or transported to a drying line or room to remove any excess moisture. Here are the different methods used to dry the molded products:

– Natural Drying

Drying the products naturally under the sun can be chosen if you are matching up to these conditions. You are only dealing with a small capacity of 1000 to 1500 pieces per hour, and there is enough wind and heat in the area: https://bestonasia.com/small-egg-tray-making-machine/.

– Brick Drying Line

You can also build or install a drying line using bricks. When you choose a manufacturer, they usually have their own engineers that will supply you with a drawing and give you advice on how to build your drying line. With the belt conveyors, the wet molded products can easily be conveyed into your drying room. Diesel or coal is the common fuel used.

– Metal Drying Line

A multi-layer drying metal line can help you to save a lot of space. This option also includes a belt conveyor that transports the wet molded products into a drying room. With this drying line, the drying line only needs assembling once you have received your goods. These lines run on diesel or natural gas.

The Packaging Process

The last step of the process involves pressing the pulp molded product with the use of a hot-press machine and then packing with the use of a baling press. Beston Group offers the equipment which can support your business greatly.