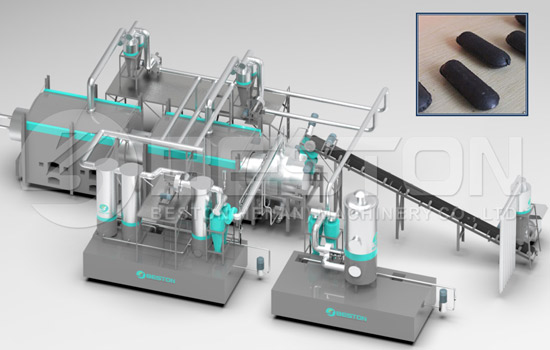

Egg tray making machines are sold in a variety of configurations including fully automated production lines, semi-automated production lines as well as manual machines. All these configurations have their own advantages and limitations. In this article, we will explore the several advantages of investing in a manual machine and how you should go about buying the right one for your business.

Pros and Cons of a Manual Machine

One of the biggest advantages of a manual egg tray making machine is its relatively cheaper price. It makes sense for businesses where all the work is typically performed by family members. It also makes sense in locations where the cost of labor isn’t overwhelming or in places where there is a shortage of electricity or other power sources.

The biggest disadvantage of a manual machine is lower processing capacity and obviously, the lack of automation. All the processes need to be performed manually and that takes a lot of time. However, it also means that the operational costs are lower as compared to a semi-automated or fully automated production line.

Choosing the Right Machine

Several manufacturers of these machines exist in the market. Obviously, every manufacturer claims their machine to be the best in terms of efficiency and production capacity. However, you also understand that such claims should always be taken with a big grain of salt. This is why you should do your own research before buying a particular model to ensure long-term success of your business. Here is a list of the important factors that matter in the long run.

Processing Capacity of the Machine

These machines are sold in processing capacity ranging from a few dozen trays per hour to several hundred or even more than a thousand products per hour. You should choose a capacity based on the demand for the product and the availability of labor. It is obvious that you will need to engage more workers to produce more products and that will increase your operational cost.

Number of Molds That Can Be Used

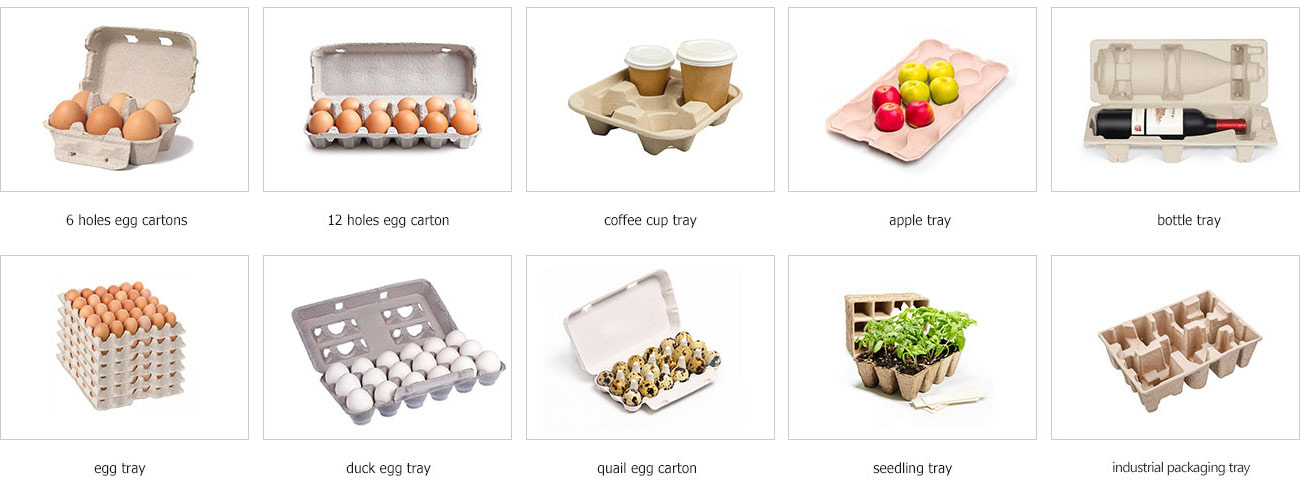

The aim of these egg crate making machines for sale is to mold the slurry made from wastepaper into solid products in the form of egg trays, fruit trays or other similar products. These shapes are achieved with the help of molds. Some machines are capable of using more than a dozen different molds which obviously provides better flexibility in terms of type of products that can be sold in the market. On the other hand, some machines are capable of using only a couple of molds which obviously limits the type of products that can the manufactured using the same machine.

Quality of Components

Reputed manufacturers use high quality materials and components for their machines. Use of higher-quality components translates into a much longer service life and less frequent breakdowns or shutdowns due to need for repairs and maintenance. Obviously, high-quality machines are going to cost a bit more as compared to machines made from poor quality components. It is better to invest in a high-quality machine as it turns out to be much cheaper in the long run. Find high-quality machine here: https://pulpmouldingmachines.com/egg-tray-making-machine/.

Overall, there are several advantages of investing in a completely manual egg-tray making machine in a location where labor is cheap or there are problems with availability of electricity. When it comes to choosing a manual machine, it is important to focus on the quality of components, number of molds that can be used inside the pulp moulding plant as well as its production capacity in order to get the best value for your money and ensure the long-term success of your business.