A very important material that is used on various construction projects is sent that can actually be produced. When most people think of sand, they think of the beach, where it can be gathered with machines. However, it’s much more efficient if you have your own source of sand that does not deplete the environment. You can produce your own by finding a sand making machine that is essentially a rock crusher machine for sale that has a specific calibration. If you are in Indonesia, you can find a quality sand making machine that you can use to produce this material for your business.

How Is Sand Made?

Sand is a material that can be made over the course of time. It typically begins with large boulders that will gradually erode due to the elements. This could be wind, water, and other forms of erosion. As smaller pieces of the rocks begin to break off, they will gradually become smaller. Through the natural process of erosion, sand beaches all over the world have been formed. To take this process into your own hands, you will need a machine that can replicate and accelerate this process. That is where a sand making machine comes in. You can see more video of this machine from AIMIX on Youtube here.

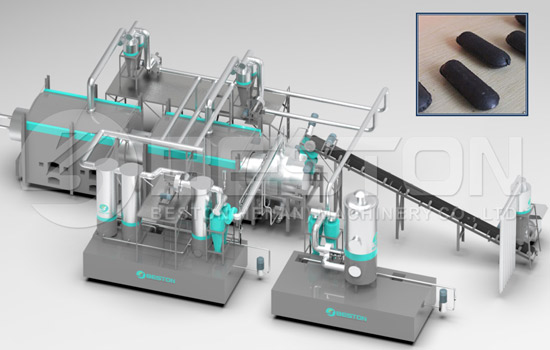

What Does A Sand Making Machine Do?

When you look at a comparison of artificial sand compared to natural sand, there are some discernible differences. Natural sand is going to have very rough shapes, very sharp edges, and corners that are not rounded for the most part. On the other hand, when you use a sand making machine, this is all adjustable.

Artificial sand tends to be very uniform in size, and you can calibrate each machine that you have to produce a very specific type of sand for your company. It does so grinding materials that have a low hardness ratio such as gypsum or bluestone. You can even begin with harder materials that, after using tertiary and secondary cone crusher, you can gradually create the sand as well.

How To Find Sand Making Machines For Sale

Businesses that specialize in working with rock quarries and mining operations often have rock crushing equipment. It often begins with a simple jaw crusher that will break down this material. This will likely move into a cone crusher that will make the material even much smaller in diameter. That is when you will begin to use artificial sand making machine Indonesia that will finish the process. You can locate these companies by searching for industrial businesses that work with contractors. Once you have found several companies, request estimates on their machines and choose one that will work with your business.

If you want to produce as much sand as possible, you will need the latest sand production machines. These are very easy to find, especially online. This is where you can find advertisements for them. Contacting the manufacturers is the next step, followed by receiving their estimates. Look at the output, sides of the machine, and when it can be shipped to make your final decision. If you have always wanted to produce your own sand for personal use, or for your business, begin looking for the best sand production machines today.